44 polypropylene vs polyester labels

Polypropylene vs. Polyethylene - Difference Wiki Polypropylene is highly modifiable, adaptable and moldable while Polyethylene is very sturdy and not easily pliable. Polypropylene is abbreviated as PP and polypropylene are known as PE. Polypropylene is known for its adaptability and its ability to be molded through the heat while propylene is known for its ability to withstand cold temperatures. Polypropylene (PP) vs Polyethylene (PET) Plastic - Brand My Cafe Blog PP plastic resists heat from outside better than PET. At the same time, PET plastic resists cold from outside much better than PP. Both PP plastic and PET plastic have a wide range of temperature resistance and the superiority of one kind of plastic over the other kind of plastic is by thin margins.

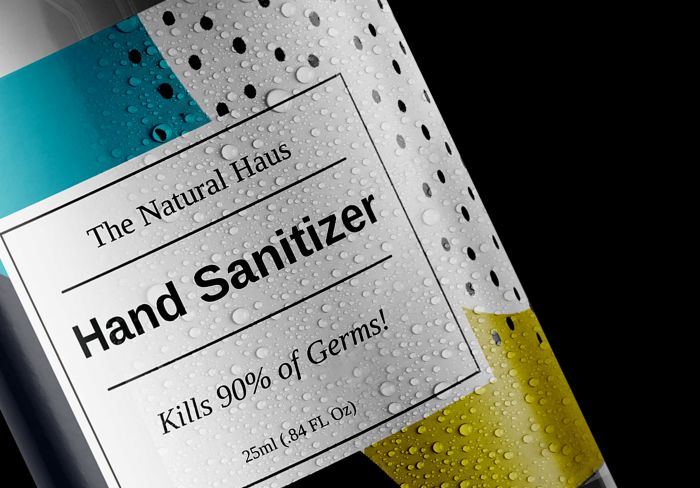

Polypropylene Labels - Polypropylene Labels ... - PA Labels Australia We offer high quality polypropylene labels that are manufactured and printed to order. Our polypropylene labels are suitable for food, personal care, cleaning products and more. Promotional stickers made from polypropylene are also popular for marketing and events. Polypropylene (PP) labels are a widely used alternative to vinyl labels.

Polypropylene vs polyester labels

Polyester Waterproof Labels - Blank or Custom | OnlineLabels® Polyester is known for being a very durable and strong material. In clothing, we know it for its resilience to abrasion, mildew, chemicals, and more. Many of those valuable qualities can also be found in polyester labels. These white labels are designed for rugged applications where a waterproof label is required. A Guide to Polyester, Nylon, & Polypropylene Fabric Polyester is typically a soft fabric, but it's made from plastic and is scientifically known as polyethylene terephthalate. The advantages of polyester include: Can be blended with natural fibers to reduce shrinkage Lower production costs Stain resistant UV resistant Pet-friendly The disadvantages of polyester include: Fabric Characteristics: Polypropylene vs Polyester - U.S. Air ... Polypropylene: Max Continuous Operating Temp: 170 Deg F Abrasion: Excellent Energy Absorption: Good Filtration Properties: Good Moist Heat: Excellent Alkalines: Excellent Mineral Acids: Excellent Polyester: Max Continuous Operating Temp: 275 Deg F Abrasion: Excellent Energy Absorption: Excellent Filtration Properties: Excellent Moist Heat: Poor

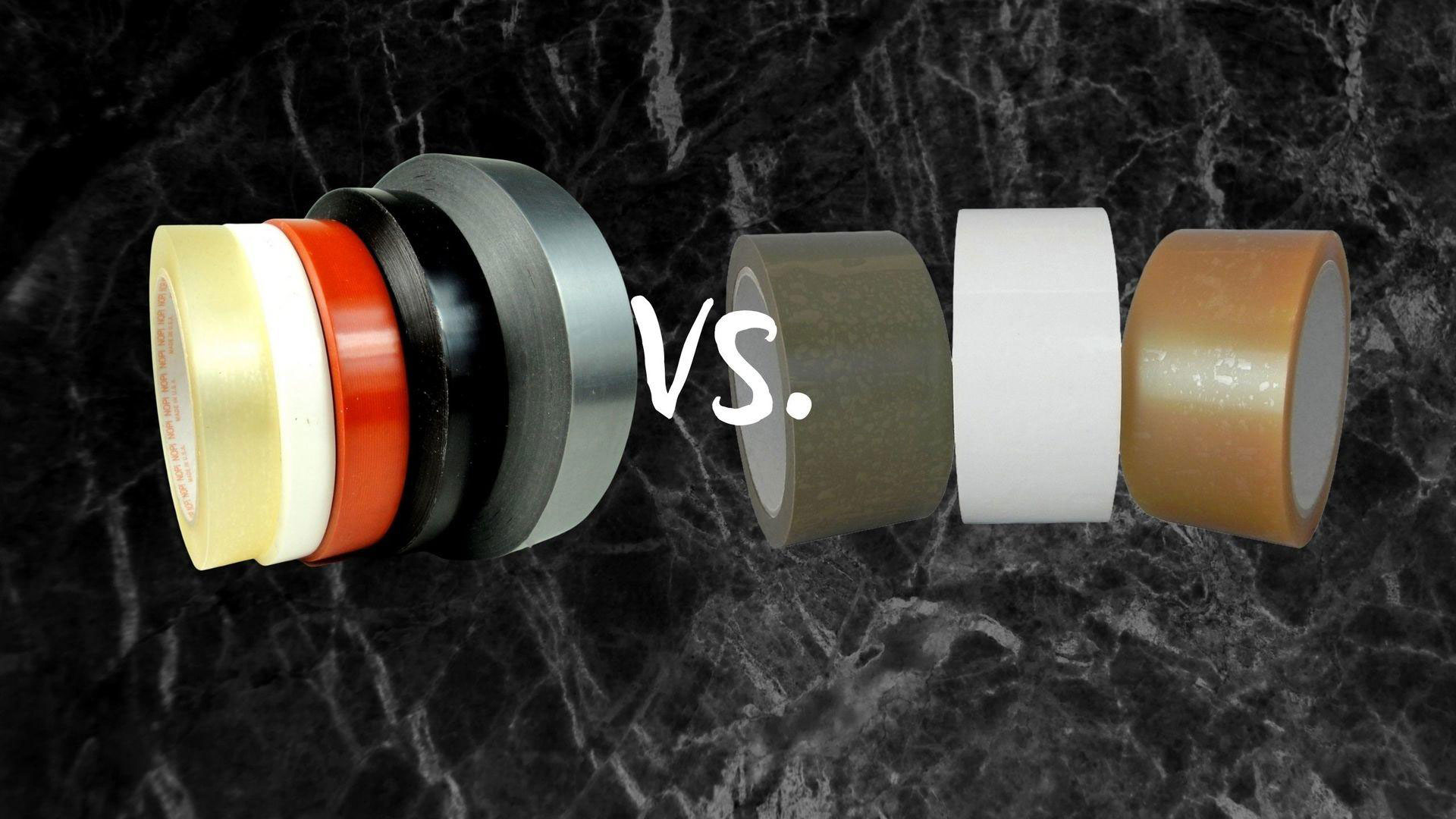

Polypropylene vs polyester labels. Polypropylene vs Polyester Strapping - PackagingSupplies.com The first is polypropylene which is usually a dull finish and most of the time has a waffle-like embossed design on it. Polyester on the other hand has a very glossy and shiny finish. If you can't tell from plain sight, simply try to tear the strapping in half. In other words if the strapping is ½" wide, try to tear it so you have two ¼" pieces. Polypropylene Labels: What You Need to Know | LabelValue They are more durable than most labels and are tear-proof and waterproof. It is also resistant to fading and discoloration that is often characteristic of standard paper labels. Polypropylene labels are ideal for a wide range of retail packaging uses, such as hair care, cosmetics or pharmaceutical products. Polyester vs Polypropylene Strapping: What's the Difference? Look and feel - Polyester strapping is glossy and smooth. Polypropylene strapping has a matte finish and is usually embossed. Tension retention - Polyester retains tension over a long period of time. Polypropylene has low retained tension, often losing about half of the applied tension with an hour of being applied. Polyethylene vs Polypropylene: Which Is Better? Aside from these, polypropylene has excellent mechanical properties and high resistance to fatigue, impact, heat and freezing. It is highly resistant to corrosion and chemical leaching, making it ideal for storing solvents, bases and acids. Polypropylene is the second most commonly used plastic after polyethylene.

FAQ - Should I Choose Paper Or Polyester Labels / Coloured Or ... Benefits and Disadvantages of Paper Labels. As a material, paper is much more readily available than polyester and polyethylene, which means that it is much more likely that your chosen paper labels will be available for same day despatch from stock (in either packs of 25 sheets or boxes of 500 sheets). We are also able to offer a larger range ... Barcode Labels and Tags | Zebra Every Type of Label. With more than 400 stocked ZipShip paper and synthetic labels and tags - all ready to ship within 24 hours - Zebra has the right label and tag on hand for your application. From synthetic materials to basic paper solutions, custom to compliance requirements, hard-to-label surfaces to easy-to-remove labels, or tamper ... Polyester Vs. Polypropylene - What's The Difference? Fluid will pass through polypropylene without getting absorbed into the fibers. Polypropylene is better at repelling water. Although polyester can wick moisture too, it is no match for polypropylene. Polypropylene will wick moisture very fast, resulting in speedier drying. 3. Durability What Is the Difference Between Polyethylene and Polypropylene? Polyethylene and polypropylene are plastics composed of polymers. Most polymers may be broken down into discrete components that serve as the polymer's building blocks; these single units are monomers. Polyethylene's monomer unit is ethylene, while polypropylene's monomer unit is propylene.

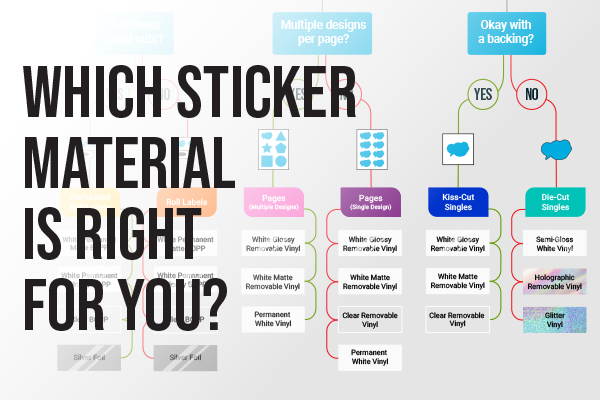

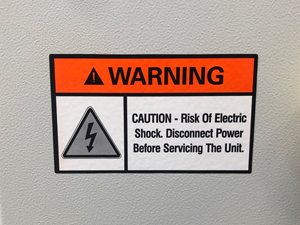

Polyester vs. Polypropylene - Difference Wiki The main difference between Polyester and Polypropylene is that Polyester is a polymer formed by condensation polymerization between a dicarboxylic acid and a diol, whereas Polypropylene is a thermoplastic polymer that is formed by the addition polymerization of propylene. Polyester vs. Polypropylene — Is There a Difference? ADVERTISEMENT Is Polyester or Polypropylene the Right Choice for my Sleeves and Bags ... Polypropylene is also archival safe, however it is gas permeable. Polyester sleeves and bags are more rigid than polypropylene counterparts. This gives polyester bags a brilliant, shiny surface. Polyester bags are strong and unlikely to tear, while the flexibility of polypropylene bags may be a better solution for some needs. Ensuring your labels withstand your environment | Blog | CILS Typical application for polyester labels: pumps, valves, motors, actuators, electronics and enclosures. Polyimide (PI) Polyimides provide a very good level of durability, especially to extreme heat of up to 730.4°F. Typical applications for polyimide labels: SMT PCB assembly. Vinyl (PVC) Poly Labels - Mylar, polyester, polypropylene, vinyl, polyolefin Poly labels really means a custom printed label made of a poly film material like Mylar (polyester, referred to as PET), polypropylene (commonly referred to as BoPP), or polyolefin (a combination of plastics made for a particular use). Vinyl labels and polystyrene labels can also be called "poly labels".

What do the different types of plastic based labels mean- PVC,PP,PET ... PP = Polypropylene PET = Polyester BOPP = Biaxially Oriented Polypropylene PS = Pressure Sensitive Vinyl is mostly used for wall and floor graphics with an indoor application. Cheaper than polyester. Polyprop is a cheaper form of polyester, also mostly used for indoor application Polyester is the most expensive, basically weatherproof.

What is the difference between Polyester and Polypropylene labels? BarcodesInc. Polyester is the most rugged and is made for outdoor or extreme temp/chemical environments. Polypropylene is great for indoor use when you need something stronger than paper and not at a high cost like Polyester. Ask us your Barcode, POS, or RFID questions. 1-800-351-9962. Filed under: Question and Answer. Posted November 29, 2012.

Polypropylene vs Polyethylene Label Materials: - Paramount Labels Metallic Polypropylene Labels: The PP label material has the same water and oil resistance as White PP and Clear PP. However the difference is in its light reflecting properties - the same as that of a metal. Colourwashing these materials are favoured by luxury brands for a magnificent display of Gold, Copper, Silver and Rose Gold effects.

What is the difference between polyester and vinyl sticker? - Camaloon The polyester stickers are printed using next-generation laser printers that print onto material with a thickness of 58 μm. The technical efficiency of our printing allows us to produce large quantities. The vinyl adhesives are printed using Inkjet technology onto material with a thickness of 80 μm. The print definition is flawless, as is the ...

Polyester vs Polypropylene: What's the Difference? - Silver Bobbin Polypropylene is more water-resistant than polyester because it transfers moisture instead of absorbing it; this makes it ideal for certain athletic wear. Polypropylene dries very quickly and also retains heat, which is why it is often used in thermal clothing. Polyester will absorb some moisture, though it is moisture-resistant.

Polyester vs vinyl labels | Electric Arc - ArcAdvisor An option for added durability is to include a standard overlaminate which will add protection from harsh environments including many chemicals, oil, gasoline, many acids, grime and abrasion. Polyester - another option you have when it comes to tough label materials is polyester.

Polypropylene and Polyester, Oh My! - Different Carpet Types and ... So yes, polyester is a very practical type of carpet for those looking to add more color to their home. Cost: $2.50 sq.ft. ($23 sq.yd.) Benefits of Polyester Carpet. Similarly to polyester, this carpet costs much less than other types such as wool. Another benefit is it is a hypo-allergenic fiber so it's perfect for those with bad allergies.

Polyester vs. Polycarbonate Graphic Overlays | Label-Aid Systems, Inc. Polyester Overlays. Generally, polyester is considered the more durable material option. You might choose a polyester label if your applications involves chemicals such as acids, solvents, or cleaners because polyester has better chemical resistance. Polyester has a higher actuation life as well, which means that it can be pushed many times ...

Do You Need Help Choosing A Label Material? - ABLT Expense - Polyester is generally the most expensive of the three label materials. Polypropylene Labels Generally referred to as Polypro, PP or BOPP (Biaxially Oriented Polypropylene) is great low-cost moisture resistant film best used for items with a short life span.

Polypropylene vs Vinyl Stickers. Comparing Custom Label Printing ... In many cases, custom polyester labels are more cost-effective than vinyl because they are less durable. Polys are manufactured to be economically viable options for many label applications, however they are costlier than paper and there is a range of price depending on the specifications of the poly.

Fabric Characteristics: Polypropylene vs Polyester - U.S. Air ... Polypropylene: Max Continuous Operating Temp: 170 Deg F Abrasion: Excellent Energy Absorption: Good Filtration Properties: Good Moist Heat: Excellent Alkalines: Excellent Mineral Acids: Excellent Polyester: Max Continuous Operating Temp: 275 Deg F Abrasion: Excellent Energy Absorption: Excellent Filtration Properties: Excellent Moist Heat: Poor

A Guide to Polyester, Nylon, & Polypropylene Fabric Polyester is typically a soft fabric, but it's made from plastic and is scientifically known as polyethylene terephthalate. The advantages of polyester include: Can be blended with natural fibers to reduce shrinkage Lower production costs Stain resistant UV resistant Pet-friendly The disadvantages of polyester include:

Polyester Waterproof Labels - Blank or Custom | OnlineLabels® Polyester is known for being a very durable and strong material. In clothing, we know it for its resilience to abrasion, mildew, chemicals, and more. Many of those valuable qualities can also be found in polyester labels. These white labels are designed for rugged applications where a waterproof label is required.

Post a Comment for "44 polypropylene vs polyester labels"